Alternative Trimming – KBS Tour Shafts

Clubmakers can often become bewildered when it comes to tip trimming a golf shaft. That is why it is important to read the directions carefully before you cut the tip as you can affect the final flex of the shaft. For instance, you purchase a stiff flex shaft. However, you may miss an important trimming note or your eyes go over one column or row too many and inadvertently trim the 3-iron shaft for a 4-iron or vice versa. All of the sudden you ruined the shaft…or did you?

When a manufacturer provides trimming instructions, it is often a suggestion rather than an absolute. What I mean by that is a shaft manufacturer is making a round tapered tube that is designed to fit into a variety of manufacturers club heads that may not all weigh the same nor will be the same final length. In many cases, at least with unitized parallel tip shafts, the trimming can be modified by the clubmaker to create an alternative flex as long as they are consistent in their methodology. This gives the clubmaker flexibility when it goes to custom fit and build a set for their customer.

Due to space limitation, it is impossible to provide all the scenarios possible when trimming a particular shaft. Therefore most clubmaking catalogs or websites will provide only one set of tip trimming per shaft to keep things simple. But I would like to go over one shaft line that goes beyond and provides alternative tip trimming.

KBS Tour Tip Trimming

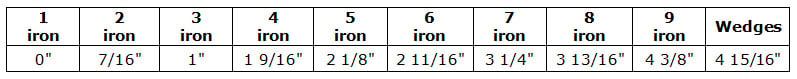

The parallel tip version of the KBS Tour are produced with a generous 43.5” length and come in 3 different flexes (R, S and X) or what I am going to say are “blanks”. The trimming instructions provided are the following.

When you buy an S-flex shaft and follow these trimming instructions, you end up with an S-flex. But what exactly is an S-flex? KBS shafts are designed by Kim Braly. If you don’t know who he is, he and his Dad (Dr. Joe) were responsible for creating the FCM (Frequency Coefficient Matched) system – a patented system in the 1980s geared at frequency matching golf shafts / clubs. Instead of a flex designation of S or stiff, flex was designated by a numerical format such as 5.0, 5.5 or 6.0. You might be more familiar with those flex designations as part of the Project X and Rifle lines as True Temper acquired the company Kim originally worked for in the early 2000’s.

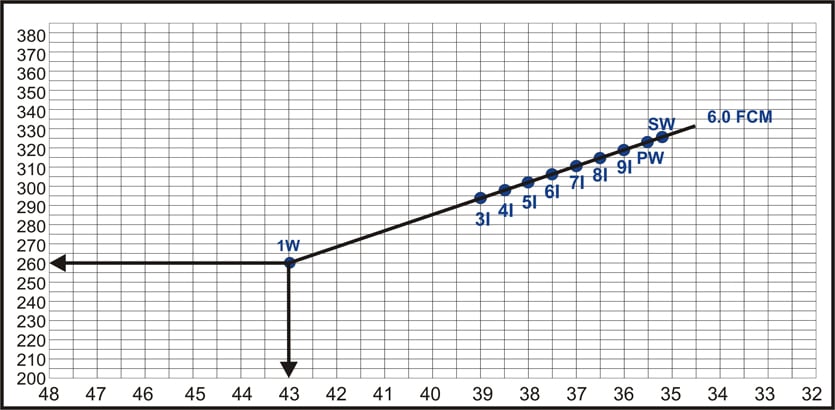

Explanation of the FCM flex levels

If you are wondering what 6.0 represents, it is short for 260 or the frequency (cycles per minute) the clubs oscillates at when clamped at the butt end and set in motion. A 5.5 flex would be 255 cpms as you simply drop the decimal point and add a 2 in front of it. However, the 260 cpm was for only one club in the set as we shall see from this chart. At the time, drivers were 43”. They were also steel shafted when the system went in place. While neither condition exists today, the system still works and that is the beauty of it.

The flex designations were built around the club that was 43” long and as the clubs became shorter, the frequency would increase at a rate of 4.3 cpm per ½” or 8.6 cpm per inch. For instance, if the 3-iron was 39” long, the frequency would be higher than the driver. Doing the math, 4 inches times 8.6 cpm would be 34.4 cpm added to 260 for a total of 294.4 or 294 for short to remain a 6.0 flex. In another example, within the set could be a 36” 9-iron. Here it is 7” shorter times 8.6 cpm or 60.2, plus 260 cpm for a total of 320.2 or 320 if rounding. When plotted, you would see a perfectly straight line suggesting a perfectly matched set. This is of course assuming that you are working with the same shaft as well as making sure the swingweights are identical as well. Plus there are a few other considerations such as consistent hosel lengths and insertion depths.

Back to our original question, when you buy a KBS Tour S-flex shaft and follow the trimming instructions, what do you end up? In the FCM system, it would equate to a 5.0 flex or the lower end of what a standard weight S-flex shaft would be. In clubmaking circles, one full flex is considered to be 10 cpm. In our example it would be from 5.0 to 6.0 (remember that is short for 250 and 260 cpm at the 43” club).

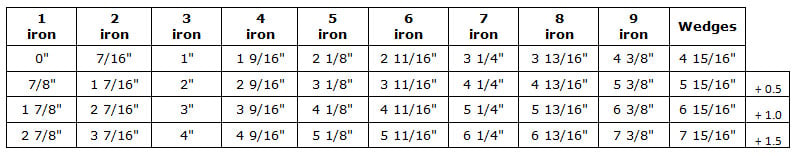

Creating additional flexes by adjusting tip trimming

The parallel tip version of the KBS Tour S-flex iron is extra-long (43.5”) and has ample parallel tip section (11.5”) that if you were to cut more off of the tip than what was listed earlier, you could create several other flexes and still have enough length for standard length assemblies. For instance, if you were to tip trim an extra 1” off of the tip, it would increase the flex by 5 cpm or increase the flex level by 0.5. Instead of trimming 2 1/8” off of the tip of the S-flex for the 5-iron we trimmed 3 1/8”, we would end up with a 5.5 flex. Trim an extra 1” and it becomes a 6.0 flex. Finally, tip trim 1” beyond that and the shaft becomes a 6.5 flex.

It is pretty common, at least in steel shafts, to have what is referred to as “combination flex” shafts, which allows usually two flexes by following one set of trimming instructions or another. Now you have seen how one long shaft can become 4 distinct flexes by altering the trimming instructions.

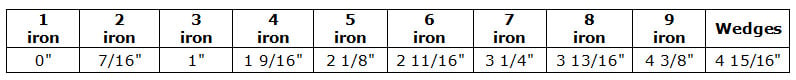

If we had bought the R-flex shaft and followed the trimming below, we would end up with a 4.0 flex.

By adding up to three inches of tipping, we create a range from 4.0 to 5.5. Furthermore, if we had purchased the X-flex and used this trimming table, then we create a 6.0 flex. Again by adding up to three inches of tipping, we create a range from 6.0 to 7.5. By trimming more off of the tip, we create not only a stiffer shaft, but one that will launch the ball lower. This will lead us to our next topic for next week talking about “Flighted” shafts.