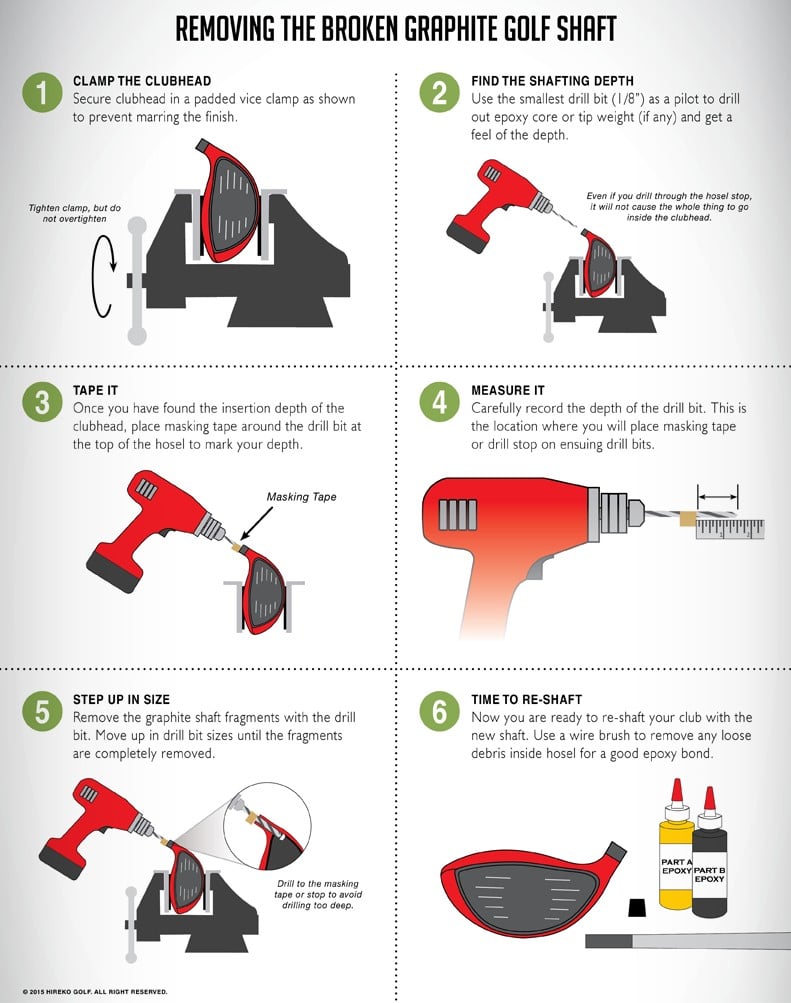

How to Remove a Graphite Golf Shaft Flush with the Hosel

One of the more common repairs that clubmakers will encounter is repairing a broken club. From time to time a graphite golf shaft will break, sometimes through no fault of the user. If a graphite shaft happens to break several inches above the hosel, then the standard routine is for the clubmakers to use a graphite shaft puller like we show here in our article called: How To Remove a Graphite Golf Shaft

But what happens when the shaft breaks off flush with the top of the hosel and you have nothing to grab onto? No, taking the head to church, dipping it into the holy water and praying the piece of shaft falls out is not an option. However, the following is a good safe way to remove the broken off piece of graphite shafts from the hosel on modern drivers, fairway woods and hybrids.

Here are some additional tips:

- Don’t try to drill the broken piece of shaft all out at once unless you know absolutely for sure what the insertion depth of the head is. Remember, manufacturers do not publish this information.

- The final bit size for a head with a 0.335” hosel is an 8.6mm bit. You can also use an R size letter bit (0.339”) or an 11/32” bit (.343”), but you will be removing some material from the actual hosel and making it larger not to mention much more work for yourself. For a 0.350” hosel use an 8.9mm bit and for a 0.370” hosel a 9.4mm bit.

- To aid in the process, you can also use a drill press with some sort of clubhead fixture to securely hold the hosel.

- If you do drill through the hosel stop and push it into the head, it is extremely difficult if not impossible to remove it in the hollow chamber. You might be able to contain it with a product called Rattle Trap.

- Additional hosel stops are available at component suppliers. These are merely dropped down inside the hosel with the recessed portion pointed downward into the opening to act as a cap.

- Do not try this procedure if you have a steel shaft broken flush with the hosel. We will have a separate “How To” article on how to tackle that problem.