Affordable. Adjustable. Introducing The High Performing Acer XV Fairways & Hybrids

For both the Acer XV fairways and hybrid we use a “hybrid” construction that combines forging and casting techniques to create the most economical and highest performing product.

For most companies, they continue to produce their stainless steel fairways and hybrids the same way they have for years. After all this is done because stainless steel is an excellent material to make a durable club at the modern size and weight as well as one that is cost effective for both the manufacturer and end consumer. But you know, every once in a while you need to shake some things up and change the way you do something in order to make improvements and that is exactly what we did with the Acer XV series of fairway woods and hybrids.

“Hybrid” construction

There are a two basic ways you can construct a stainless steel fairway wood or hybrid. One is the way that most companies choose and that is the investment cast method. In brief, this involves producing multiple tooling to create what will eventually be a hollow bodied structure. Wax is injected into the molds and melted onto to wax frames which are then dipped into ceramic slurry several times until it creates a ¼” shell around the wax. They are then heated so the wax drips out so later molten stainless steel can be poured into the shells. Once cooled, the ceramic is broken off and cleaned away and cut from the “tree” to form the “as cast” parts. Then the process begins to weld the pieces together, grind, polish and then finish it into the final product you see. As you can imagine it is labor intensive.

The second method is “forging”. In brief, this process involves stamping out sheets of stainless steel over forming tools and cutting away the excess material. Then the welding, grinding, polishing and cosmetic finishing takes place. This is a much easier process, but the downside is one cannot stamp really intricate shapes or wall thickness like you can with the casting method unless one wants to invest in very expensive forged tooling. However, this method is faster and is more economical.

For both the Acer XV fairways and hybrids we use a “hybrid” construction that combines forging and casting techniques to create the most economical and highest performing product.

Multi-material construction

Not only are we using hybrid construction but also employing varying grades of stainless steel. The crown is forged from 420 stainless so we can shed needless weight to be better able to use elsewhere. The thicker sole is cast from 431 stainless steel as well as the rest of the head (or the high performance part) that will need further explaining.

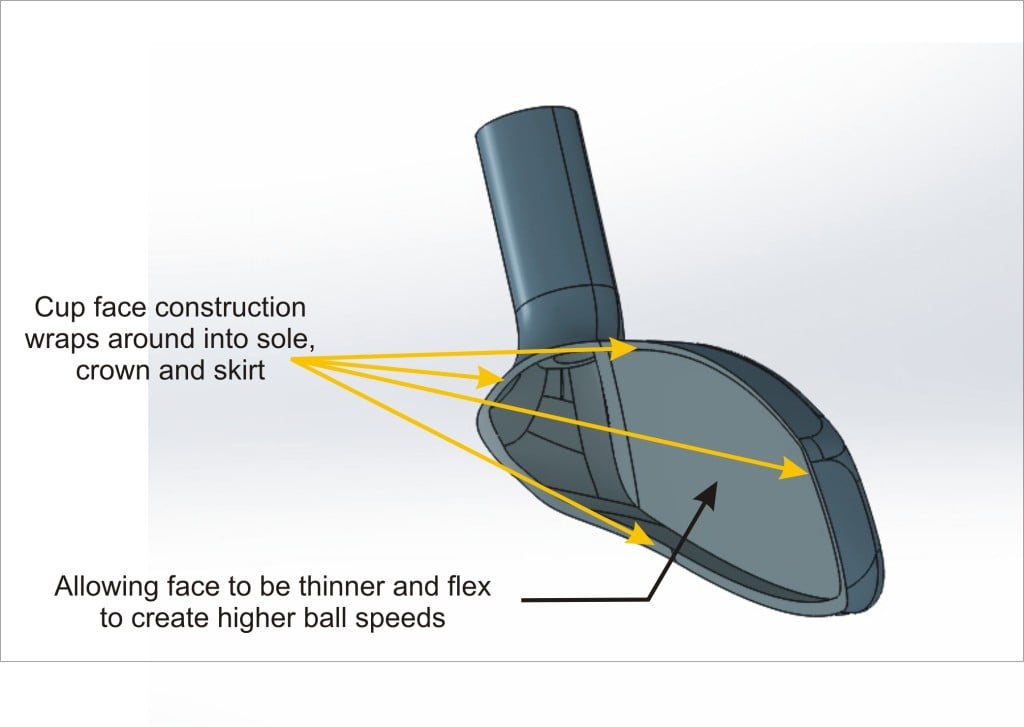

Cup face design

One of the keys to a high coefficient of restitution (COR) is a variable face thickness. As we said before, this is best by using the casting technique. We also chose a cup face structure to round out the XV series to enhance the variable thickness. You will also notice from the CAD picture the third piece includes the hosel as part of the face to save welding (extra weight) and distortion (tolerances in face angle and lie).

In golf club cup-face construction, part of the faceplate is incorporated into the sole, crown and skirt area of the head. This pushes the weld back away from the actual face. By moving the weld further back away from the face, the areas around the perimeter could be made thinner and deflect more, thus producing a higher ball speed to areas other than the center of the face as compared to traditional welding techniques. Even when you miss-hit the ball, clubs with cup-face technology provides you that extra spring-like effect for longer, straighter shots.

In golf club cup-face construction, part of the faceplate is incorporated into the sole, crown and skirt area of the head. This pushes the weld back away from the actual face. By moving the weld further back away from the face, the areas around the perimeter could be made thinner and deflect more, thus producing a higher ball speed to areas other than the center of the face as compared to traditional welding techniques. Even when you miss-hit the ball, clubs with cup-face technology provides you that extra spring-like effect for longer, straighter shots.

Other enhancements

Like the matching drivers and Acer XV Thriver Mini in the Acer XV series, these feature the Power Chamber Sole (for greater energy transfer to the ball) and the Gravity Port (for fine-tuning swingweight with different weight shafts and custom lengths). The Gravity Port is also moved forward for reduced spin as another distance contributor but at the same time there is a very high concentration of weight in the sole to produce a high launching head. The stock screw is 7 grams, but you can also get 2g and 12g replacement screws which allow for options galore.

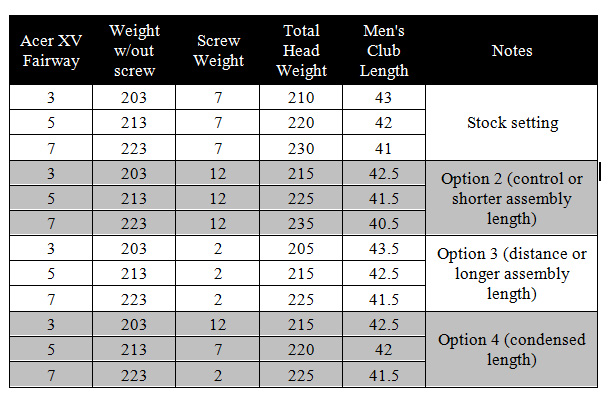

Fairway options

For the fairway woods, this chart shows 4 different options available to clubmakers. After all, not all golfers are the same height or have the same needs. For example taller golfers may want longer clubs, but may not want the higher swingweight as a result using standard weight heads. Conversely, shorter golfers may prefer reduced length clubs but still want head feel only available by having a heavier weight head. Option 4 is for those that typically struggle with a 3 wood, but may not with the 5 wood. In that case it is not the loft, but rather the length that is the problem and this helps remedy it.

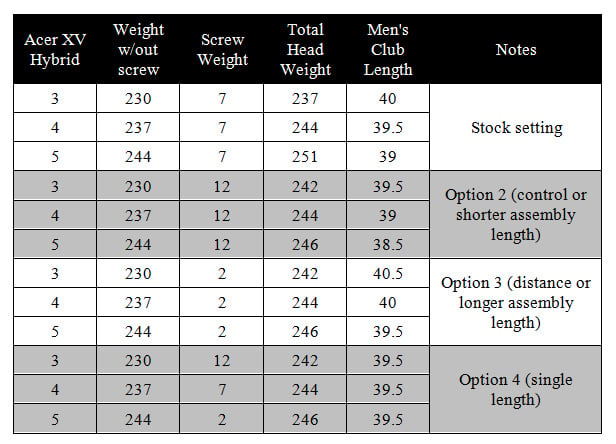

Hybrid options including the Single length option

Hybrid options including the Single length option

For the hybrids, here are the 4 options as well starting with the stock settings.

Option 4 is the intriguing one as the weight allows for a single-length approach. There are some golfers that are single-length iron proponents as this allows for a repeatable swing when all the clubs are the same length, lie and swing with the only thing changed is loft. Option #4 or #2 may be an excellent option for beginners or high handicapped players looking for improved solidness of contact. However note it is not possible to alter the lies so they can be the same lie single length irons are.

Option 4 is the intriguing one as the weight allows for a single-length approach. There are some golfers that are single-length iron proponents as this allows for a repeatable swing when all the clubs are the same length, lie and swing with the only thing changed is loft. Option #4 or #2 may be an excellent option for beginners or high handicapped players looking for improved solidness of contact. However note it is not possible to alter the lies so they can be the same lie single length irons are.

Add up the all the features

As you can see, there is a lot going on and yet we are charging far less than other manufacturers offering not nearly the technology or adjustability. The Acer XV fairways can be mixed and matched with the rest of the Acer XV family for you to create the perfect set make up. Or you can purchase one of these separately to fill a gap or replace a club that just isn’t cutting the mustard anymore.