Is Bore Type Relevant in Clubmaking Today?

I am going out on a limb here, but sometime in the not-so-distant future, you will begin to see bore types in woods change.

How the times are a changin’. This year when I was proofing and editing our upcoming 2014 catalog I realized something, those special trim notes that give our clubmaking customers fits is soon to be a thing of the past. Many customers are already confused about how to trim a shaft, especially the trim note about bore type.

A. For M1 metal woods add 1 1/2″ tip trimming, for M2 metal woods add 1″ tip trimming, for blind bore add 1/2″ tip trimming, for through bore do not add to tip trimming. (Applies only to those shafts which have a Trim Note A next to the letter code)

They ask, “Do I need to follow that trim note or don’t I?” Well I can safely say this; the only shaft this will apply to all of next year is True Temper’s Dynamic Gold wood shaft. That’s it – and you know how few steel wood shafts you see installed into clubs today. (Note, the Dynamic Gold wood shaft is no longer available)

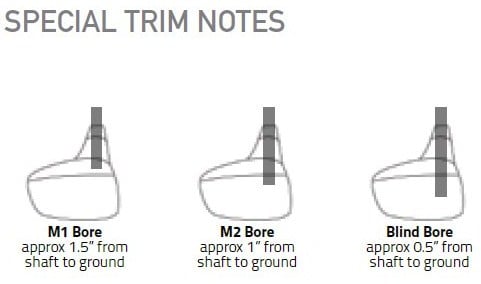

However, I am going to take this opportunity and treat this as a teachable moment as there are a few other trim notes that apply to bore type that you will need to understand. Here is a diagram with captions describing three of those bores. The missing one is through (or thru) bore which penetrates through the bottom of the sole. Almost all manufacturers will lump our M1 and M2 bore designations together and call them a “standard” bore metal wood even though there are no standards.

However, I am going to take this opportunity and treat this as a teachable moment as there are a few other trim notes that apply to bore type that you will need to understand. Here is a diagram with captions describing three of those bores. The missing one is through (or thru) bore which penetrates through the bottom of the sole. Almost all manufacturers will lump our M1 and M2 bore designations together and call them a “standard” bore metal wood even though there are no standards.

The same concept even applies to irons where we are concerned with the bottom of the bore to the ground line (BBGM). In most irons, standard is considered 1” and if you work on older Callaway irons, the shaft went through the bottom of the bore (bore thru). But it is not uncommon to see blade-style wedges with a 1.5” BBGM or higher.

Does bore type matter then?

A long time ago when wooden woods were the only choice for golfers, the shaft penetrated thru the sole or what would be call a bore thru design. Shaft manufacturers designed their flex around that. Over time as a way to save time is assembly, manufacturers began making the bore of their woods to stop just short of going through the sole. This became a blind bore design or where the tip of the shaft would rest approximately ½” above the ground line.

When metal woods came about in the late 1970’s, the shaft would seat much higher off of the ground than their wooden counterparts. In order for the flex to be as designed, shaft manufacturers began suggesting tip trimming their shafts for the bore type. At this point in time, the shafts were all parallel tipped and allowed for this type of practice.

In the late 1980’s, Callaway became popular with their S2H2 hosel (Straight, Short, Hollow Hosel or essentially a bore thru hosel). Initially the S2H2 started in their irons and eventually became a staple in their woods. Once again there was resurgence in shaft manufacturers designing their flex and recommended tip trimming around this type of bore due to their volume and popularity. It wasn’t too much later that Titlist also followed with a thru bore designs in their woods, but this time with a much longer hosel or insertion depth.

The effect of bore type on shaft flex

Bore type directly affects the final flex of the shaft / club and here is why. The difference in the BBGM of a M1 (or standard metal wood) versus a blind bore head today is 1”. By inserting the same shaft into two heads with the only difference being their bore type, then the blind bore club will be stiffer. How much? It would be almost the same as if we were tip trimming the shaft an additional 1”. When you put it in that context, then most of you will understand it is noticeable.

Today, there are no new heads with bore thru hosels. This is good for clubmakers and repairmen as this is one less laborious step to perform. But in the same token, there is no industry uniformity in the BBGM amongst woods, hybrids, irons and wedges today. Again, this is the reason one shaft in one head may feel slightly different when installed into another head. With offset drivers or drivers with interchangeable adapter systems, it is not uncommon for some heads to have the BBGM as high as 2”. Guess what, shaft manufacturers have been slow to adjust and thus the reason why drivers today are a little more flexible than they were just a few years ago.

A few manufacturers might make special notes on a through bore and blind bore heads not to insert the shaft beyond 2” as not to make the shaft any stiffer. While you may not encounter this unless you are re-shafting older clubs, be aware of it. You will most commonly find these trimming indications from Aldila and Graphite Design.

Future of golf club bore type

I am going out on a limb here, but sometime in the not-so-distant future, you will begin to see bore types in woods change. What was once popular will come back into favor. Plus with all the talk about launch angle and spin rates, bore type can affect those too. But just because you may not have to be concerned with our infamous Trim Note A doesn’t mean that bore type will become irrelevant.