Taper Tip Steel Shaft Primer

You may have noticed in our catalog and website that Hireko stocks both 0.370” parallel and 0.355” taper tip versions of many of the steel iron shafts from True Temper, Project X, and KBS. For those that may not know the difference between a parallel and taper tip shaft, then you may want to pay close attention before ordering a shaft.

What size fits Hireko clubs?

First off, only 0.370” parallel tip shafts fit Hireko’s irons, wedges and hybrids. In many cases the code to order the shaft will tip you off – look for the U. If you look at the first letter in the steel shaft code and it starts with the letter U, that is short for unitized. Actually it means the shaft has a 0.370” parallel tip shaft and will fit into any of our irons, wedges and hybrids. Those that do not have a U at the front mean that they have a 0.355” taper tip shaft. These will not fit any of our irons, wedges or hybrids as they will be too loose for the epoxy to hold. The only exceptions are FST the current Apollo steel shaft line where they are all parallel tip

Then why does Hireko carry taper tip shafts?

Not all clubmaking shops make their money solely from building clubs from component parts. Most shops offer re-shafting and the repair of broken shafts as their second most common procedure only after re-gripping.

Many name brand companies offer taper tip steel shafts in their pro-line irons and wedges. For instance all of Cleveland and Titleist wedges use taper tip shafts, while companies such as Ping and Mizuno offer them exclusively in their irons and wedges. Some companies elect to use taper tip shafts in their better player’s irons and use parallel tip shafts in their game improvement clubs for the everyday golfer. TaylorMade, Cleveland and Wilson come to mind.

It is the responsibility for the clubmaker or customer to measure the tip diameter of the shafts or hosel bores before ordering. But don’t take for granted a certain brand of iron or wedge will be taper tip even if you have worked on them before. It is possible that the clubs could have been worked on by someone else who re-bored the hosel to accept a parallel tip shaft. Not common – but it is a possibility.

What is the difference between a taper and parallel tip shaft?

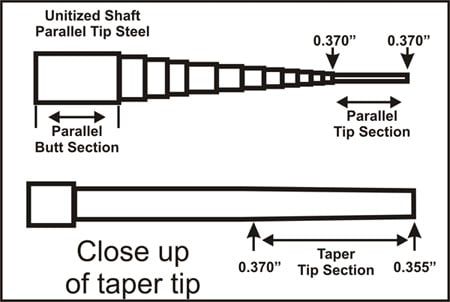

Taper tip shafts are just that – they taper! They gradually become larger from the very tip up to a certain point on the shaft. A 0.370” parallel tip shaft will start out at 0.370” at the tip and remain that way for an extended distance. In taper tip construction, the shaft tip will be 0.355” at the very tip and approximately 2” up the shaft tip will become 0.370”.

Are there playability differences between a taper and parallel tip shaft?

This all depends upon the model. Some shafts such as the Project X line of shafts, there was no difference in playability between the parallel and taper tip shafts. All that happens is the shafts for the taper tip starts out as parallel tip but are swaged or squeezed to form the taper tip section.

In other cases such as the venerable True Temper Dynamic Gold or a KBS Tour, the taper tip and parallel tip versions can be much different. One thing to look at is the weight. If the shafts are all the same weight regardless of their length (also called constant weight), expect to see differences. These differences could occur in the overall weights of the clubs, balance point (typically higher swingweight with same weight heads), frequency slope and tip stiffness.

With parallel tip construction, the shafts progressively become lighter as more it trimmed from the tip to accommodate the head. As in the case of the Rifle shafts, they have been pre-tip trimmed by the manufacturer.

Why do you need different lengths in taper tip shafts?

Each raw length is designed specifically for a different head. The reason for this is the flex is built in to compensate for the head weight. The beauty of the system is this allows the clubmaker or manufacturer to skip one step in the assembly process by not having to tip trim the shaft. Essentially the manufacturer has already performed this step for them so all they have to do is epoxy the club and butt trim to length.

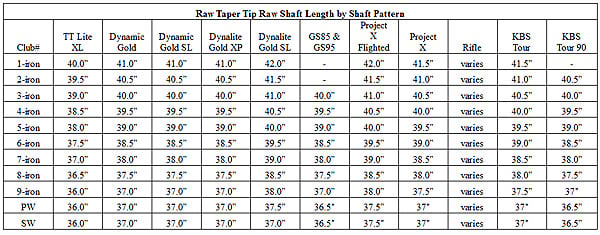

Below is a list of the taper tip shafts Hireko offers with their raw lengths and suggested club to go into. The sole exception was the Apollo steel Hump X-flex which came in a 39” raw length and was simply butt cut to the desired length due to the unique enhanced tip section.

Do you have to use the suggested raw length?

No, there are processes called soft and hard stepping to create different flexes. To explain, let’s start out with soft-stepping. This process involves taking a longer recommended length shaft and installing it in heavier head for the intent of decreasing the flex. For instance, a 40” Dynamic Gold shaft is designed for a 3-iron. If you put that 40” shaft in the 4-iron, the shaft will be ¼ flex more flexible. The reason is the 4-iron head is heavier than a 3-iron. By soft-stepping twice or putting the 40” raw length shaft into a 5-iron, then the club becomes ½ flex more flexible.

Hard-stepping is just the opposite in order to create a stiffer flex. For example, a 38.5” Dynalite Gold SL shaft is designed for the 8-iron. If it was installed into a 7-iron, then it becomes ¼ flex stiffer. The problem with hard-stepping is you will run out of raw length for the wedges if building a full set.

When re-shafting, you may find the major manufacturer had used a different raw length taper tip shaft than suggested by the shaft manufacturer. Now you know why as this was more likely part of their custom program.

So the next time you are ready to re-shaft a steel-shafted iron or wedge you will now have a better understanding of what to order and possibly how to install it to achieve your desired results.