Do You Need to Alter Tip Trimming with an OEM Shaft Adapter Sleeve?

One question I often field is whether a clubmaker should add any tip trimming to an OEM shaft adapter. Well the answer to that is no and I will explain why.

What is a Bonded Driver?

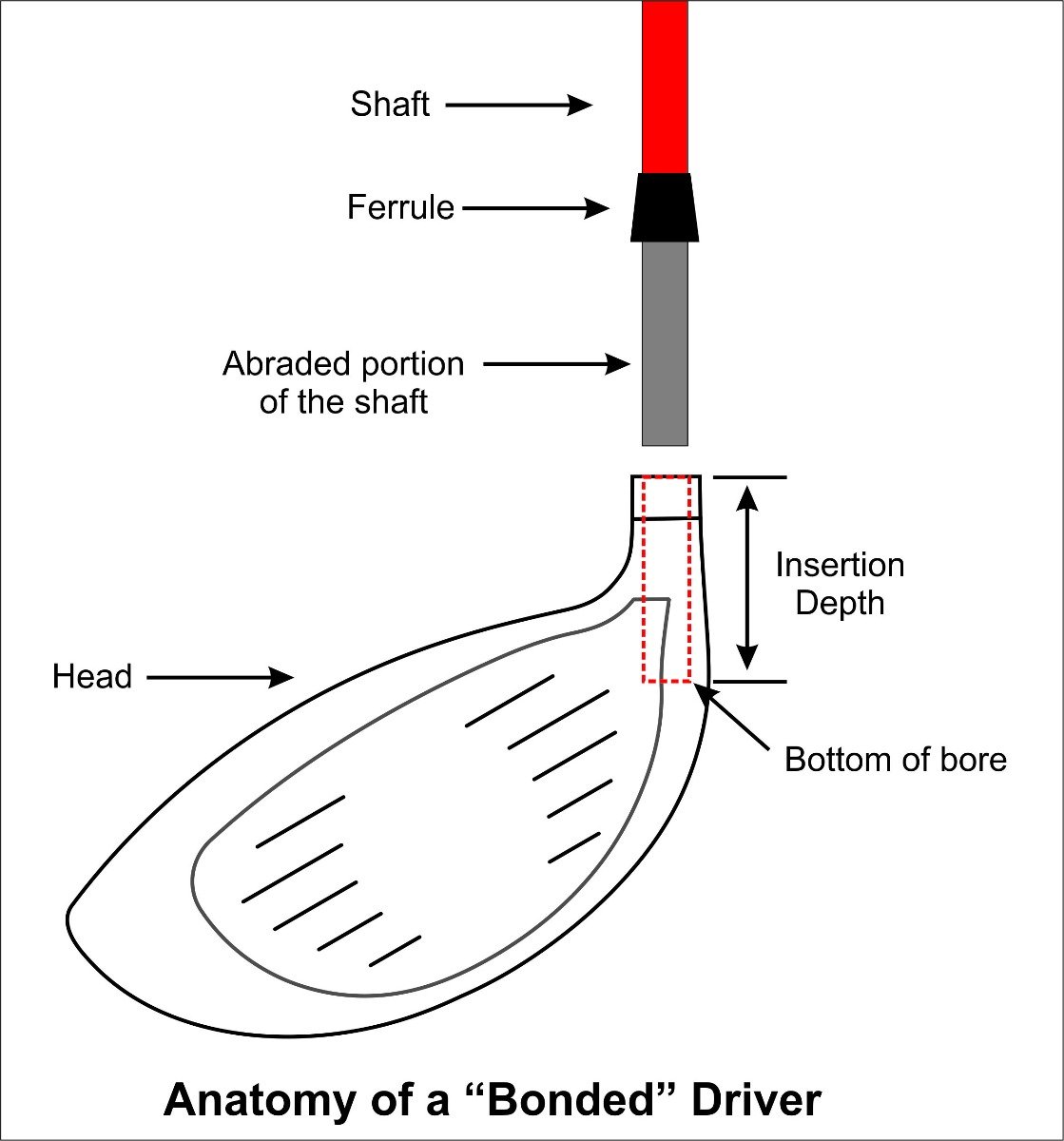

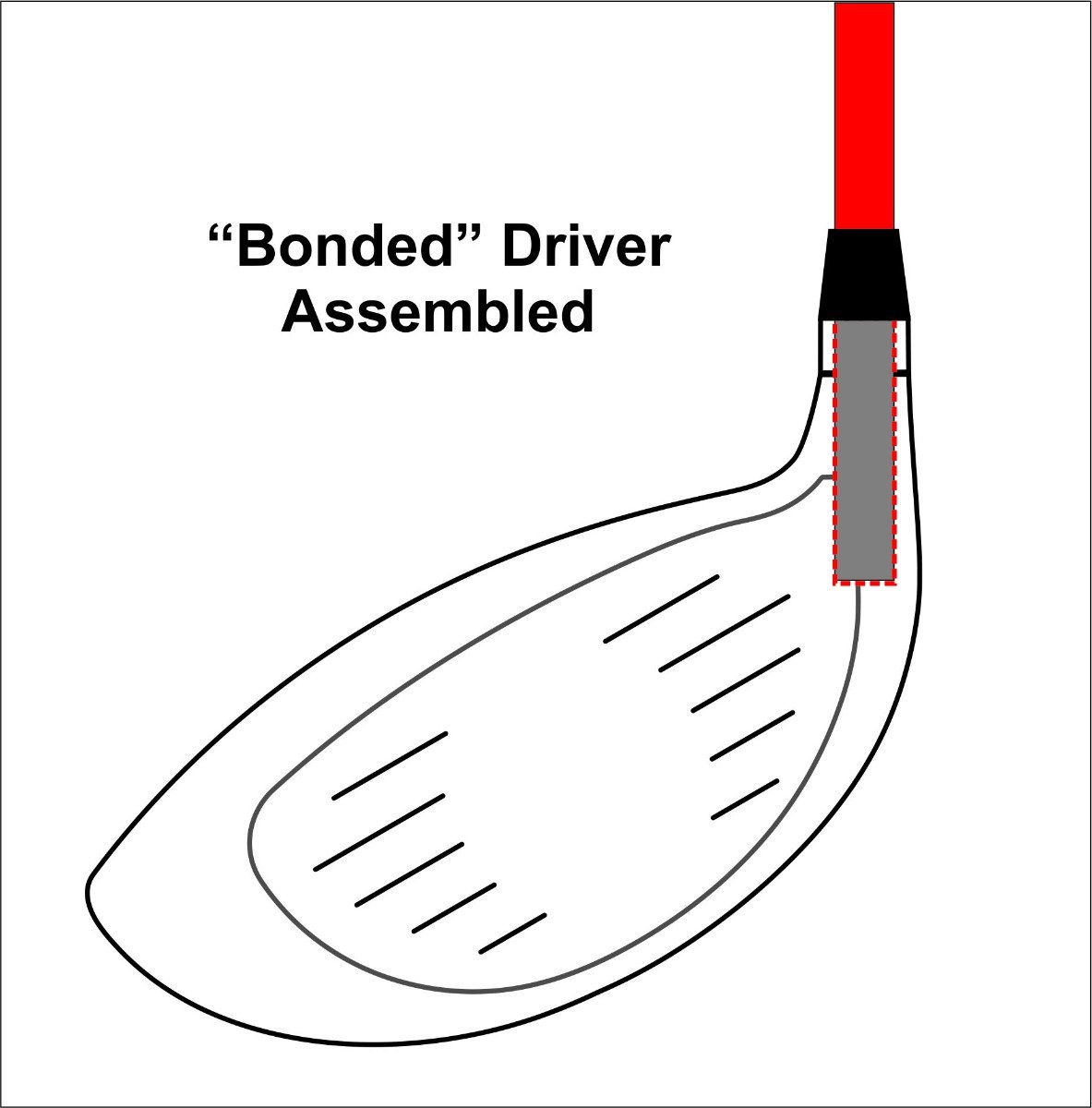

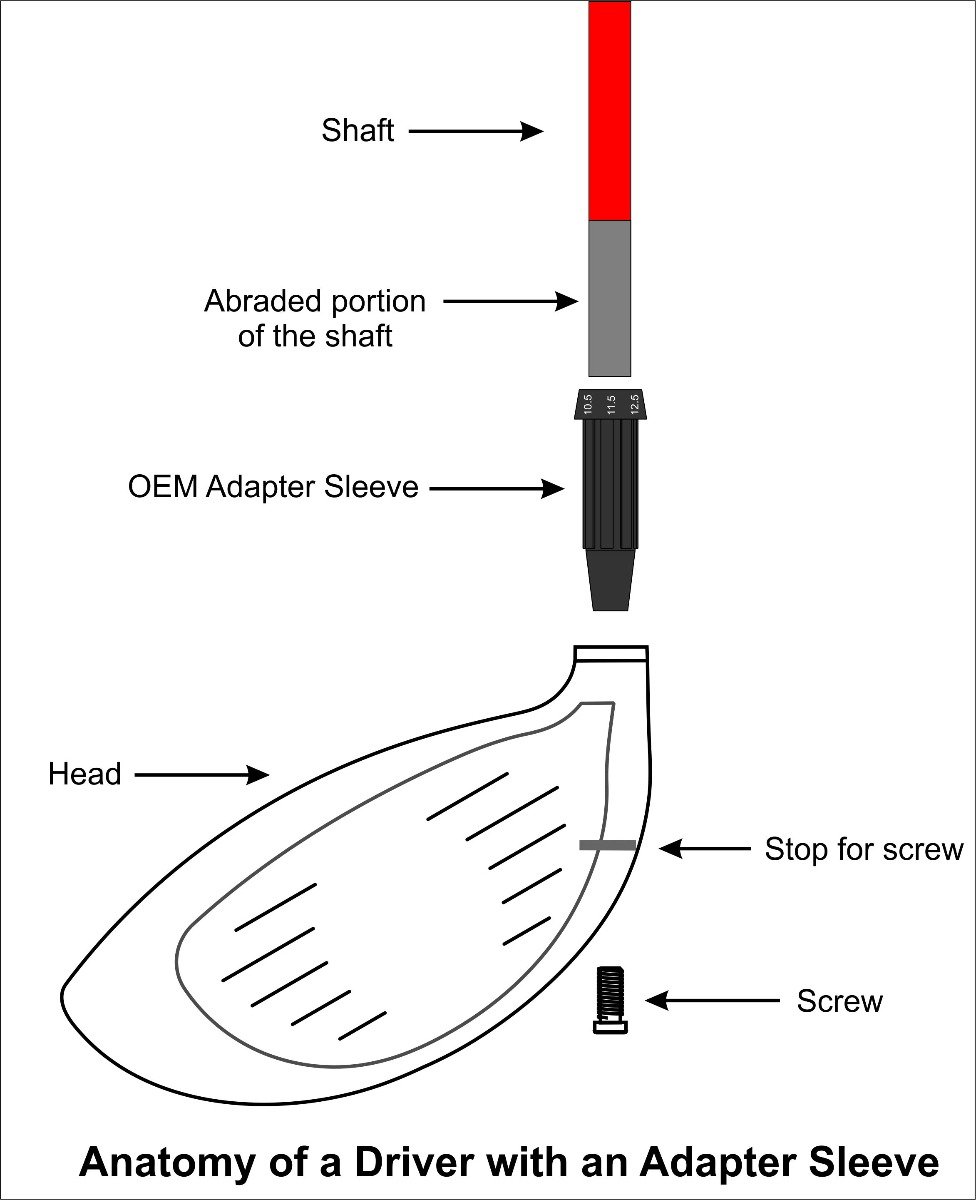

Let's first look at a "bonded" driver or one that the shaft is epoxied directly into the head. This is a picture of a modern driver, but the principles are the same for any club. The abraded shaft is epoxied into the hosel. Insertion depth or how far the shaft will seat will vary from one product to another, but the shaft should always seat at the bottom of the bore. When installed, the club looks like this on the right.

|

|

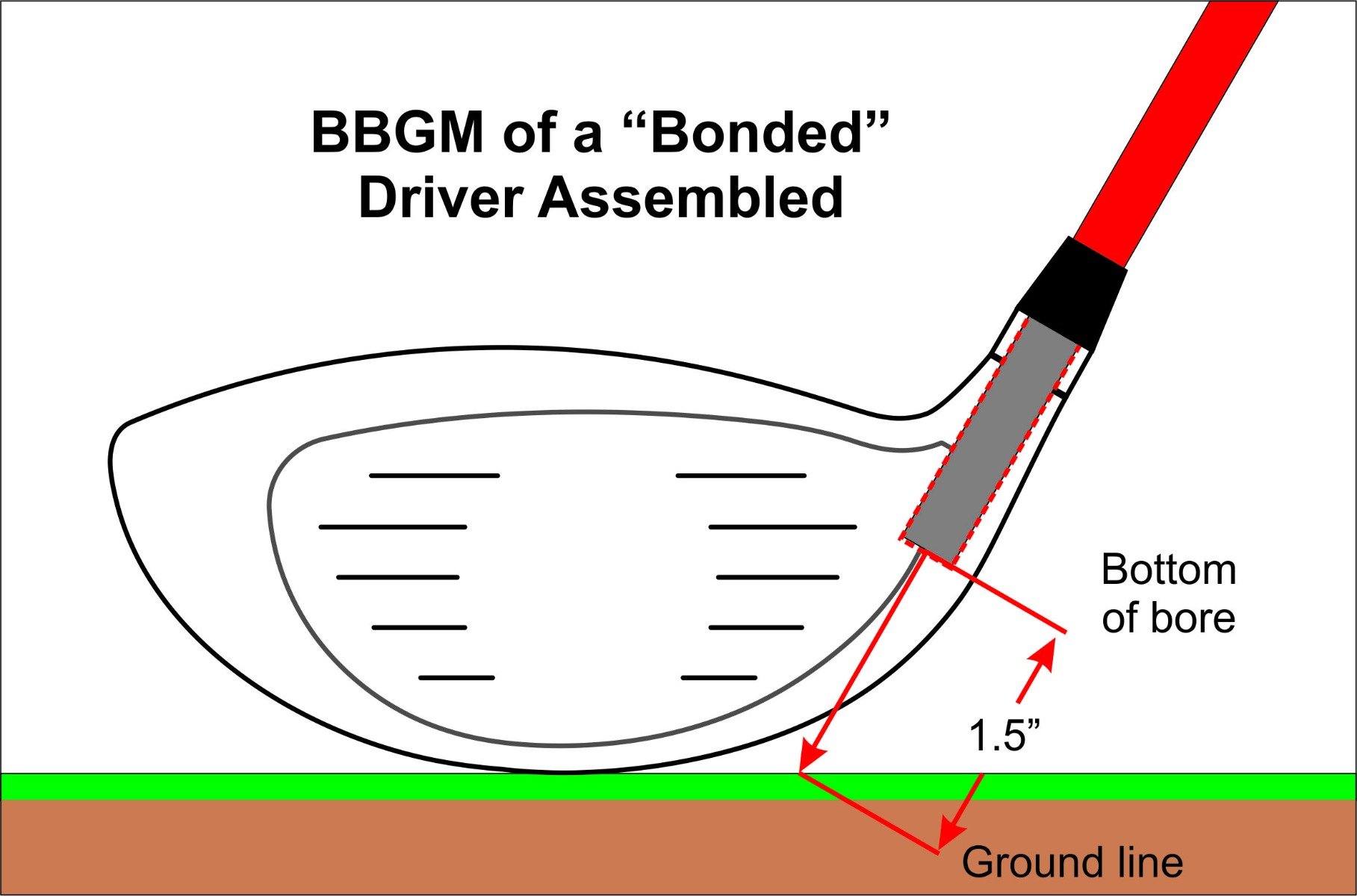

Bottom of Bore to Ground Line (BBGM) Measurement Explained

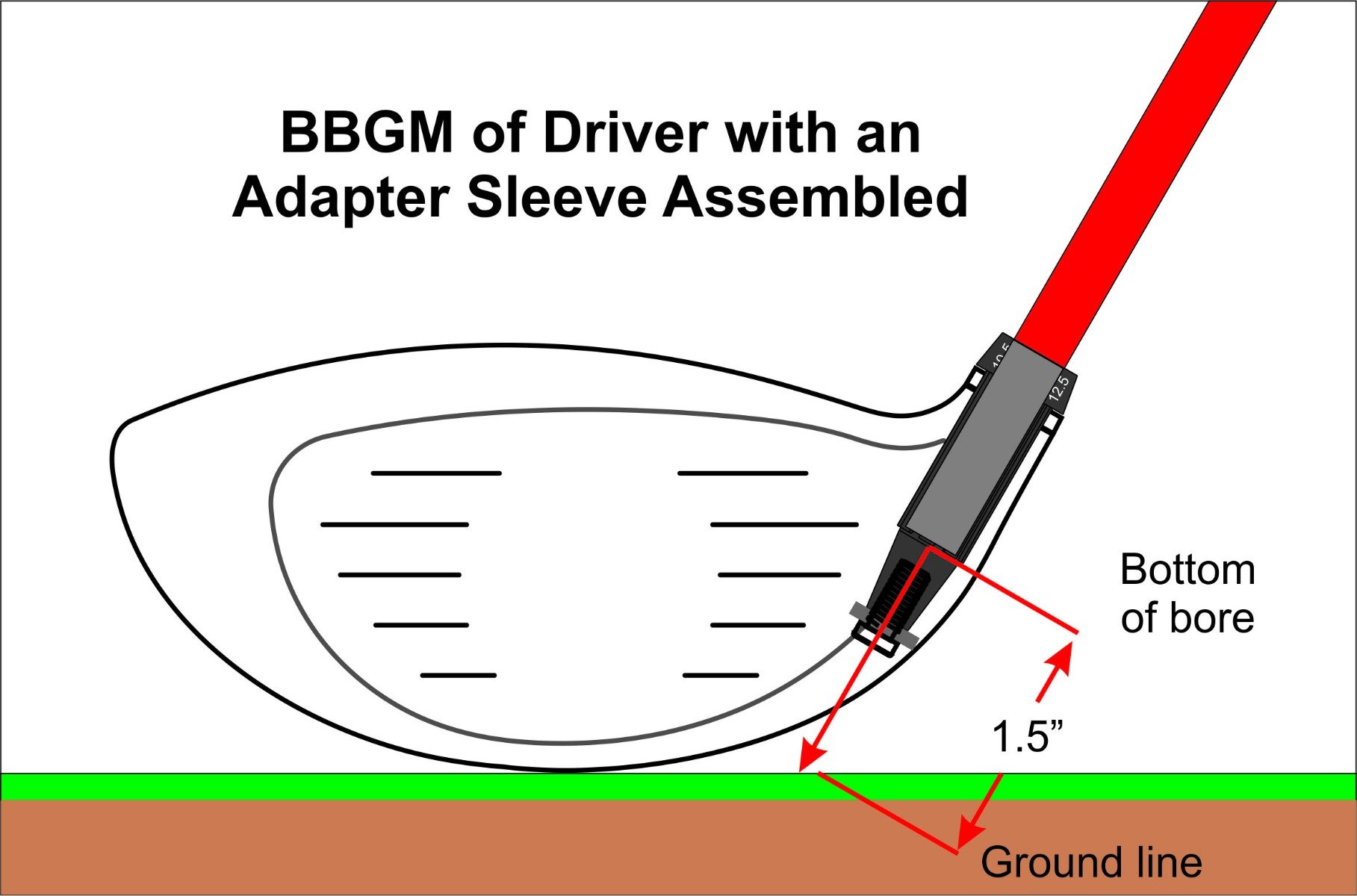

A term that clubmakers should be familiar with is Bottom of Bore to Ground Line Measurement or BBGM for short. This is simply how far the shaft tip rests above the ground when full inserted into the hosel. In our example of a modern golf driver, the BBGM is typically 1.5". Offset drivers (with the gooseneck feature) may have a BBGM close to 2". There is an easy method to obtain the BBGM on any club. First, measure the raw length of the shaft. Let's say it is 46". Next, insert it into the hosel and make sure it goes to the bottom of the bore then measure the total length of the club. Let's say it is 47.5". To obtain the BBGM, you take the total length with the shaft installed (47.5") and subtract the raw length of the shaft (46") and you get 1.5" like our example. It is that easy.

Driver with a Shaft Adapter Seeve

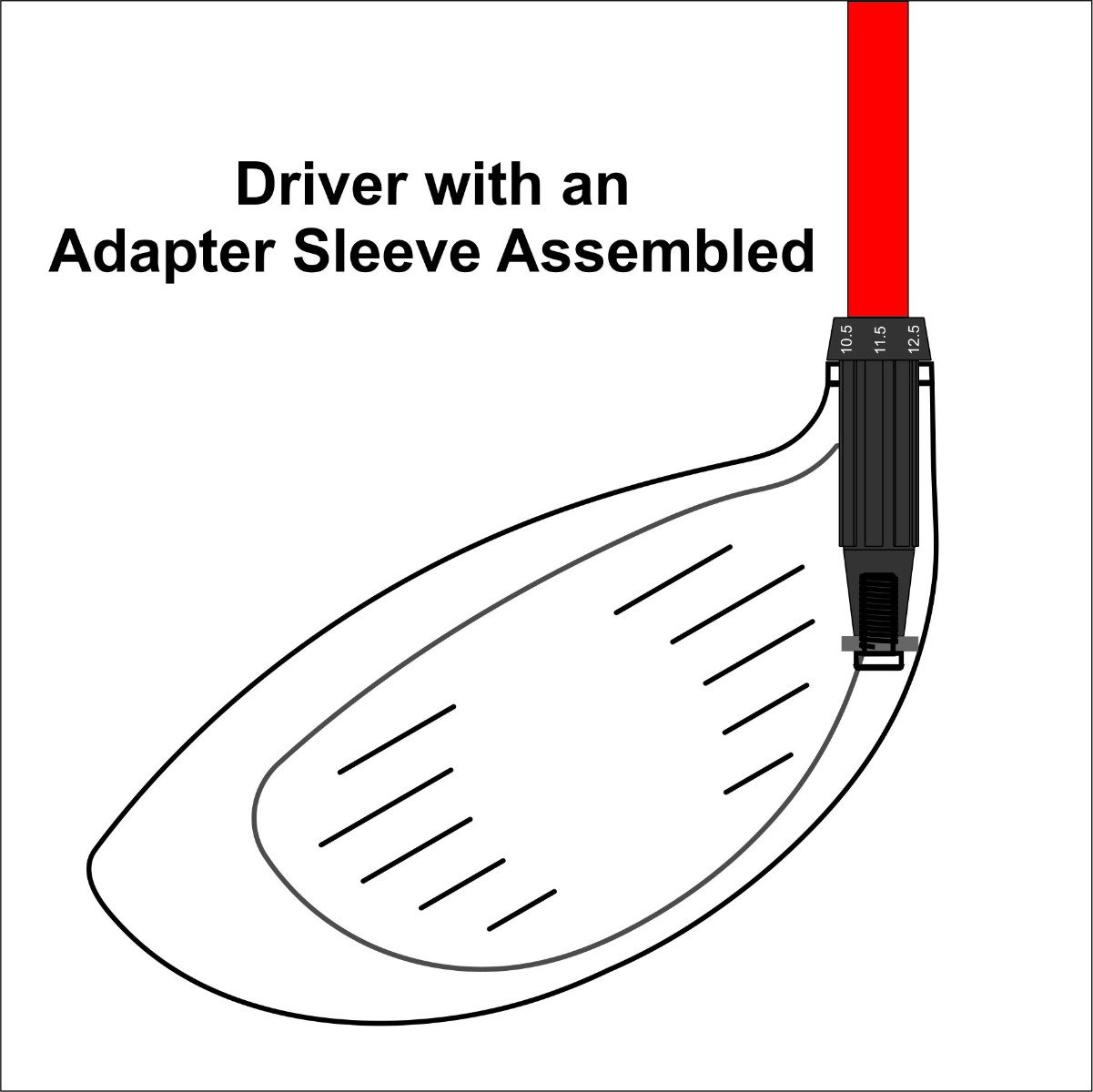

For a driver with a golf shaft adapter sleeve, the picture will look slightly different because you have one extra piece. Instead of the shaft directly going into the hosel of the head (like a bonded driver), you have the shaft epoxied into the shaft adapter sleeve. Those components then penetrate the head which is secured by a screw. The stop for the screw is viewable by looking at the bottom of the head.

|

|

The final image shows the BBGM of the driver with the shaft adapter sleeve. As you can see it is no different than a normal driver and the reason there is no need to adjust tip trimming. However, you now know how to measure for the BBGM. If the club you are re-shafting has a BBGM greater than your current driver and you are using the same exact shaft, then you could alter the tip trimming by tip trimming the difference, then the two clubs should have the same flex. That is always an option for the clubmaker.

For more information on bottom of bore to ground line measurement and tip trimming, please consult the Modern Guide to Golf Clubmaking book.