parallel tip

- August 25, 2021

Pros and Cons of sanding a graphite shaft to fit a taper tip hosel

From time to time, I get the question from a clubmaker or hobbyist if it is alright to sand down the tip of a 0.370" parallel tip graphite shaft to fit into a 0.355" taper tip iron or wedge. Before I answer the question and show what the pros and cons are, I first must mention the liability issue. Anything you build or repair, you are liable for what happens. Therefore, it is always the best practice to put in the shaft size that corresponds to the inside hosel diameter.

Why would you need to sand the shaft?

The number 1 reason why clubmakers ask is due to the lack of taper tip graphite iron shaft offerings. Of the models that are available also tend to be on the more expensive side and likely a special order, requiring additional time to fix or retrofit a customer's club.

- February 26, 2021

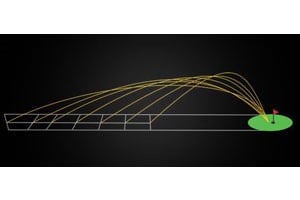

You may find from time to time that a customer is caught between two flexes. There is a way to remedy this situation called the principles of soft and hard stepping shafts. These terms mostly apply to taper tip steel iron shafts, but the concept also applies to parallel tip shafts. So, let us explain each of the four scenarios.

SOFT STEPPING

Parallel tip shafts

Let us begin with the easiest example using parallel tip shafts. The flex of a unitized, parallel tip shaft is determined by how much to trim off the tip of the shaft based on the weight of the head. As head weight increases, the amount of tip trimming increases incrementally to maintain the flex the manufacturer designed into the shaft.