It is common today for a set of golf clubs to include a mix and match of different brands and/or models, especially in the scoring clubs. For many golfers, they choose to use a wedge(s) that are not part of their matching iron set, which is perfectly acceptable. In this article, we are going to explain how to properly tip trim the shafts for the flex to remain constant, so they feel like a “set”.

Differences between a wedge from an iron set versus wedge set

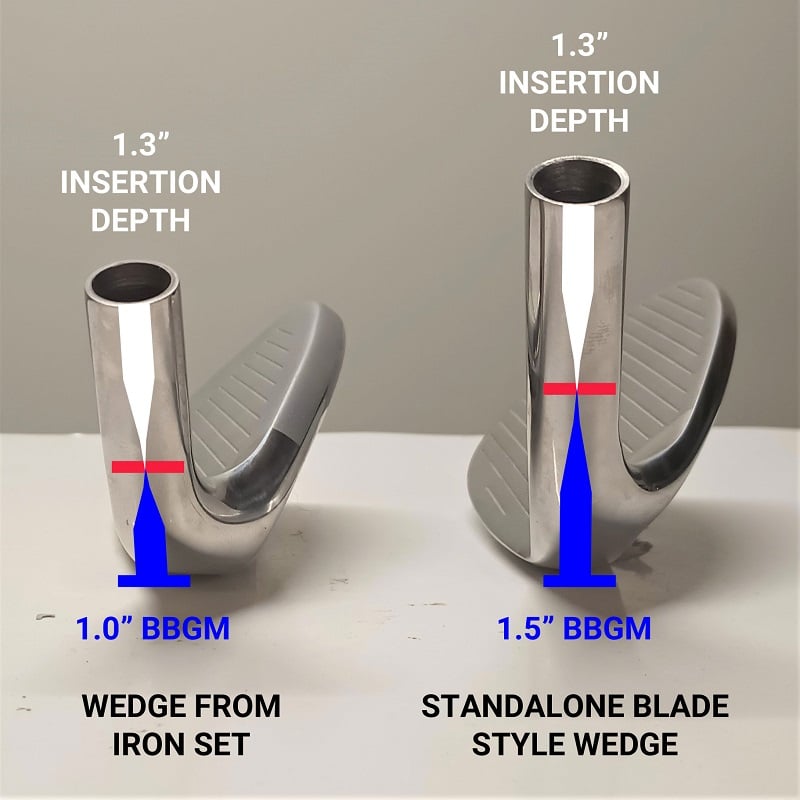

In the picture below, we have a wedge from a cavity back iron set on the left. To the right is a standalone blade style wedge. You can see several differences between the two styles of wedges like the hosel length, face height, topline thickness, etc.

However, one of the details you cannot see is how far down the shaft penetrates down into the hosel. It just happens that both wedges have the same insertion depth (1.3 inches). The red line on the hosel depicts how deep the shaft penetrates or seats when installed.

Understanding the Bottom of Bore to Ground Line Measurement (BBGM)

A term that clubmakers should be familiar with is Bottom of Bore to Ground Line Measurement or BBGM for short. This is simply how far the tip of the golf shaft rests above the ground when fully inserted into the hosel. In our example, the BBGM of the wedge from the iron set is 1.0" which is typical for a modern iron.

There is an easy method to measure the BBGM for any club. First, measure the uncut length of the shaft. Let's say it is 41". Next, insert it into the hosel and make sure it goes to the bottom of the bore then measure the total length of the club. Let's say it is 42". To obtain the BBGM, you take the total length with the shaft installed (42") and subtract the uncut length of the shaft (41") and you get 1.0" like our example. It is that easy.

For the standalone wedge, we started out with a 41” shaft. When installed into the hosel, the total length was 42.5” making the BBGM 1.5”.

How does this affect the flex of the shaft?

Below is a popular trimming chart for a parallel tip iron shaft. Let’s say we were building a matching set of irons (#5 – PW) with a 1.0 BBGM and then adding our blade style gap and sand wedge with the 1.5” BBGM.

| Flex | 2i | 3i | 4i | 5i | 6i | 7i | 8i | 9i | Wedges |

| R | 0.0” | 0.5” | 1” | 1.5” | 2” | 2.5” | 3” | 3.5” | 3.5” |

The trimming chart says we should be cutting 3.5” from the tip of all the wedges. However, if we do so for the gap wedge and sand wedge, these clubs will become more flexible. Why? Go back and look at the images of the two different clubs. If trimmed the same amount, then the tip of the shaft will be ½” higher off the ground on the gap and sand wedge. This would be the equivalent of not trimming as much from the shaft or a term called soft stepping. That extra ½” amounts to a club that is a ¼ flex softer.

To normalize the flex, we would recommend tip trimming an additional ½” for the gap and sand wedges. The result will be where the PW from the iron set and the other two wedges will have the same tip to first step dimension when finished.

What happens if you miss this step?

Having the wedges slightly more flexible will increase the ball flight. There is plenty of loft on these clubs already so it may reduce your distance. On the other hand, you may have more spin to stop the ball on the green. For full shots, you may not be as accurate with a more flexible shaft than the rest of your clubs. Then again, how often do you take a full shot rather than a partial or ¾ swing with the wedges? You can see the pros and cons of not accounting for the differences in the BBGM of these two different style wedges.

Are there exceptions to adjust for the BBGM?

There are two examples where you don’t want to make any adjustments. One is taper tip iron shafts. These are bought / sold for a particular club. If you tried to tip trim the shaft, then the shaft tip will no longer be able to penetrate down to the bottom of the hosel without re-boring it.

The other example relates to parallel tip graphite shafts. You want to carefully check the parallel tip length of the shaft or how long it remains that tip diameter from the tip end until it starts tapering. If the graphite shaft has a 5.5” parallel tip section and calls for 3.5” tip trimming, that only leaves 2” for the insertion depth of the hosel and the additional length for the ferrule. In this case, you probably wouldn’t want to try trimming the extra ½” from the tip to account for the longer BBGM. Otherwise, the ferrule may split trying to force it up the shaft.

In summary, we can see why you may want to tip trim additionally for the wedges if the BBGM is different for the wedges versus the rest of the irons in the set. This may not be possible in certain cases, but you will at least know what the consequences of not doing so.