What are the different types of golf irons to choose from today?

Currently golfers have more choices than ever when shopping for a set of irons. Because of the selections, it can make the process intimidating for those that may be new to the game or may not stay atop all the changes that have occurred in recent years. This article will shed some like on the various terms you may come upon to help educate yourself on not only the differences, but also what might be best iron for you.

Golf Iron Construction

Before we talk about the different types of irons, we must first talk about their construction. There are two main methods in which golf irons are produced; cast and forged. There is a third option, that is a hybrid construction that combines both techniques as we will mention later.

Investment Cast Irons

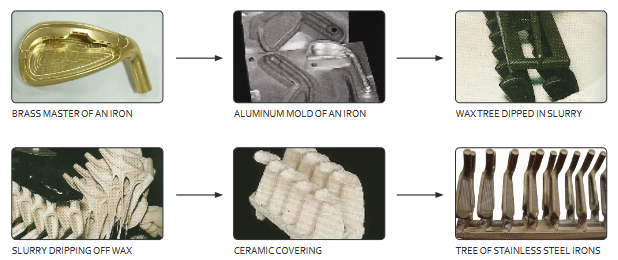

Investment casting is the method most irons today are produced through a process known as the “lost wax process”, which involves pouring (or investing) liquid metal into a mold. Most investment cast irons are produced from stainless steel, although it is possible to cast carbon steel.

Liquid wax is injected into a mold, cooled, and carefully extracted to prevent the loft or lie from being altered. Perfect wax replicas of each head (or a face and a body as in the case of a two-piece construction hollow-bodied iron) is melted to a wax frame. The wax frames, with identical numbered heads or items form a “tree”, which are then dipped several times in a ceramic slurry mixture and then dry ceramic sand to form nearly a ¼” shell around the entire tree of waxes. The building up of layers around the wax will eventually be capable of withstanding the heat of the molten metal.

Once the shell is cooled and hardened, it is placed in a controlled temperature environment where the heat and pressure force the wax out of the shells leaving behind an empty ceramic shell (basis for the term lost wax). Molten metal, typically 431 or 17-4 stainless steel will be poured into the shell and set aside to cool. Later, the ceramic shells are broken away from the steel tree and cut away from the frame leaving an unfinished “as cast” piece. The heads go through numerous finishing steps to achieve the final product. In the case of a cast carbon steel head, the final step will be chrome plating to prevent it from rusting.

Hollow-bodied irons that are produced from two separate pieces go through one additional phase. The pieces are carefully welded together, ground, polished and painted until they reach their final appearance.

Die Cast Iron

Die casting is another process of club head production (primarily used with zinc or aluminum) in which heads are formed through the injection of material into a pre-formed die. This process is generally used on lower-priced iron heads you might find in a complete starter set of golf clubs.

Forged Irons

The oldest method of manufacturing an iron is by forging. Although the process of producing forged irons has changed from hand to machine forged, it remains more labor-intensive and expensive than investment casting. The initial step involved in forging an iron involves taking a solid, tubular billet of soft steel (normal carbon steel), heating it then pressing it into the rough shape using a huge mechanical press exerting several tons of force. This allows the rough shape to be stamped out and allows only for a basic shaped plain back or cavity shapes. Through each successive step, it begins to look more like a finished iron. Some forged irons will have a separate hosel piece that will be welded to the face. I will then be turned down with a lathe to ensure a consistent diameter and finally the hosel drilled to accept a shaft.

The next steps all involve many hand operations as the faces are stamped or machined flat, stampings pressed in (or engraved) and the weight is reduced by grinding and sanding. Special care needs to be performed to make certain the radius of the sole or the general shape is replicated from one club to the next as all the hand operation can lead to greater inconsistencies than investment casting. Afterwards, the heads go through additional polishing steps to ensure a smooth surface to which chrome, nickel and/or copper are electroplated to the surface to prevent rusting and lastly paint filled.

A comparatively new forging method is now being employed by the foundries using CNC milling machines. Instead of producing everything in-house, the raw forgings can be purchased from a forging house. These will be a basic shape that possesses a plain, flat back and is left intentionally overweight. The heads are placed face down in a special fixture to hold them securely in place underneath a CNC machine to remove material in an exact manner that is programmed into the computer. This allows for virtually any cavity shape that can be made through investment casting, even an undercut channel that traditional forging techniques are incapable of achieving. Depending upon the complexity of the cavity, the milling machine may take 10 to 20 minutes to route out a single cavity. Therefore, the CNC shop will be equipped with 10 or more milling machines and running at multiple shifts to produce any type of quantity. Upon completion, the heads go through the same finishing processes as a traditional forging.

Form Forged Irons

A form forged iron will start out as a rough casting and then goes through the final steps of the forging process until the iron is in the final form. This procedure is not common but does provide one example of hybrid construction.

Iron Designs

Cavity Back Irons

Well over 95% of the irons purchased and made available today are cavity back irons. These heads are distinguished by a cavity or recessed area in the back of the clubhead. Weight is effectively removed from the central area and is redistributed to the sole, heel, toe, and topline areas of the club, hence the terminology “perimeter weighted”. The perimeter weighting helps maintain the club’s stability as there is a tendency for the head to twist less on off-center hits. This special feature offers some improvement in overall accuracy and distance.

Well over 95% of the irons purchased and made available today are cavity back irons. These heads are distinguished by a cavity or recessed area in the back of the clubhead. Weight is effectively removed from the central area and is redistributed to the sole, heel, toe, and topline areas of the club, hence the terminology “perimeter weighted”. The perimeter weighting helps maintain the club’s stability as there is a tendency for the head to twist less on off-center hits. This special feature offers some improvement in overall accuracy and distance.

Cavity back irons are available in a variety of sizes and shapes. The heads with the larger face surface area are a better match to the less consistent golfer, while the smaller head’s surface is being a better choice for those who hit the face center often. Cavity backs, which may be either cast or forged.

Undercut Cavity Irons

Another design feature in an ironhead is the undercut channel. In addition to a cavity area, a “channel” is formed between the face and rear of the club to displace more weight rearward in the clubhead for greater stability and a high launch angle. Many of the most playable irons contain this feature.

Muscle Back Irons

Also referred to as blade irons or simply blades, they are easily identified by their relatively flat solid backs (no cavity). Muscle back irons may be either cast or forged, but traditionally have been forged. Those players who consistently hit the ball in the center of the face most of the time prefer this iron design. However, they offer little in the way of game improvement; most of their weight is centered toward the middle of the club. Shots hit on either the heel or the toe will produce harsh feel and noticeably shorter, less accurate shots.

Also referred to as blade irons or simply blades, they are easily identified by their relatively flat solid backs (no cavity). Muscle back irons may be either cast or forged, but traditionally have been forged. Those players who consistently hit the ball in the center of the face most of the time prefer this iron design. However, they offer little in the way of game improvement; most of their weight is centered toward the middle of the club. Shots hit on either the heel or the toe will produce harsh feel and noticeably shorter, less accurate shots.

Very few full sets of irons sold today are the traditional blade style clubs for the simple reason that they do not offer the same resistance to twisting that cavity back irons offer. Most muscle back clubs sold today are in the form of wedges, where they are shorter and easier to make solid contact. Muscle back irons, while they may be aesthetically pleasing due to their clean lines, should be relegated as a club of choice to better players only.

Hollow-bodied Irons

As the name implies, hollow-bodied irons are made up of two pieces and welded together, like how a fairway wood or hybrid would be manufactured. By having all the weight around the perimeter, it increases the perimeter weighting and makes it less likely to twist at impact. Thus, making it even more forgiving than today’s cavity back irons. Plus, they may incorporate a face material different from the rest of the iron to produce a higher spring like effect to generate higher ball speeds. It is even possible that the body and hosel are investment cast and the face may be forged or cast.

There is even a category of hollow-bodies irons for better players or low handicapped golfers. They offer a hollow-bodied construction but may resemble a muscle back design at first look. These will feature reduced offset, a thinner topline, narrower sole and a shorter blade length, all of which a better player might prefer, but provide additional game-improvement features.

Hollow-bodied irons that are wider front-to-back or more bulbous than a traditional iron is called Hybrid-Irons or Iron-Woods. These are often the most forgiving of all the irons available and preferred for mid and higher handicap golfers. Due to the construction, materials and extra labor for welding, finishing. and polishing, hollow-bodies irons will be the most expensive cast irons.

Hollow-bodied irons that are wider front-to-back or more bulbous than a traditional iron is called Hybrid-Irons or Iron-Woods. These are often the most forgiving of all the irons available and preferred for mid and higher handicap golfers. Due to the construction, materials and extra labor for welding, finishing. and polishing, hollow-bodies irons will be the most expensive cast irons.

Utility Irons

Utility irons can be categorized as specialty irons. These are usually lower-lofted, possess a wider sole and constructed using a hollow-body design. They are an alternative to a hybrid club head for those that prefer an iron shape, but demand that they have greater forgiveness. A utility iron will normally be part of a blended iron set where they have a matching cavity back design.

Utility irons can be categorized as specialty irons. These are usually lower-lofted, possess a wider sole and constructed using a hollow-body design. They are an alternative to a hybrid club head for those that prefer an iron shape, but demand that they have greater forgiveness. A utility iron will normally be part of a blended iron set where they have a matching cavity back design.

Driving Irons

A driving iron can also be called a utility iron as this low lofted iron is designed specifically to hit shots from the tee box. While some golfers may be able to hit these successfully from a good lie the fairway, it does require high swing speeds to get the ball airborne. Typically, a driving iron is a singular club or offered in only a couple of lofts as an alternative to a fairway wood or low lofted hybrid (like a #2). They will be standalone clubs that may not match a manufacturer’s regular line of irons.

A driving iron can also be called a utility iron as this low lofted iron is designed specifically to hit shots from the tee box. While some golfers may be able to hit these successfully from a good lie the fairway, it does require high swing speeds to get the ball airborne. Typically, a driving iron is a singular club or offered in only a couple of lofts as an alternative to a fairway wood or low lofted hybrid (like a #2). They will be standalone clubs that may not match a manufacturer’s regular line of irons.

Summary

Because of hybrid design and construction techniques, there is more of a blurred line on what category an iron could fall into. Regardless, the wide assortment of irons offered today is vastly superior to your father’s irons. If you are using an older set of irons and upgrade, you will likely see an improvement in accuracy and an increase in distance.