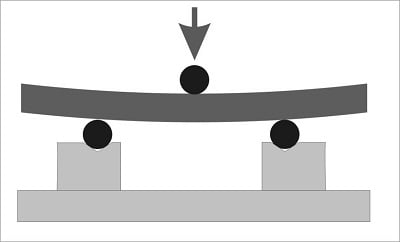

Several years ago, Hireko added a new piece of equipment to our shaft testing lab to help better quantify shaft stiffness and to educate clubmakers and customers alike to help select the right shaft. Our EI shaft profiler is a 3-point bending test that measures the deflection along the span of the shaft. By taking measurements from the tip to the butt and plotting the results provides a more comprehensive look at the shaft’s stiffness distribution and a better understanding of how that shaft will react.

To be honest, we really haven’t shared that information. Partially because we did know if clubmakers or the average golfers would understand the results. However, for you gearheads out there, here is an example of understanding the relationship between steel shaft construction, weight distribution and weight on shaft stiffness and ball flight.

Golf Shaft Terminology 101

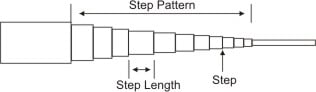

Shaft weight and weight distribution (or balance point) are two contributors to steel shaft stiffness as we will discuss later. Shaft geometry is a function of the collective diameters and the taper rate of the golf shaft. For example, we have the outside diameters and lengths of the butt and tip sections and the step pattern or rate of taper in-between.

How Shaft Weight Affects Stiffness and Ball Flight

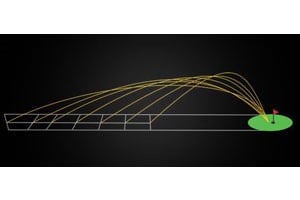

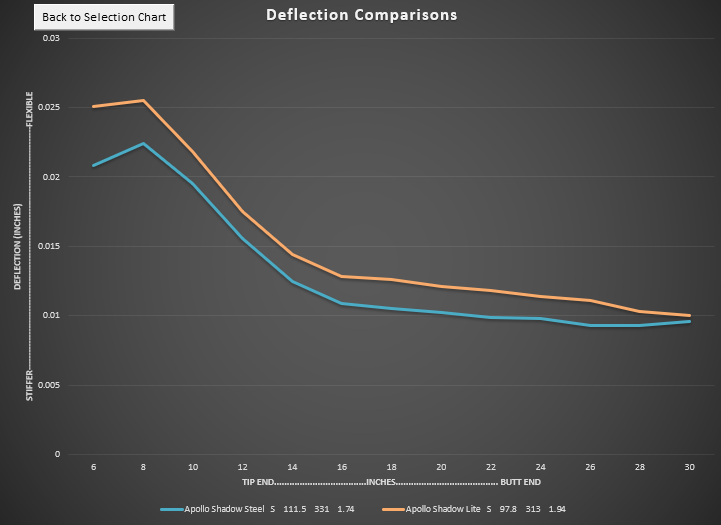

This chart below shows the deflection amounts along the length (every 2”) of two different cut 5-iron shafts from the tip (left) to the butt (right) end. The higher the reading (deflection) on the chart illustrates a more flexible portion of the shaft.

The deflection curve in blue is the original high launch/low bend point Apollo Shadow Steel S-flex shaft that has been cut for a 5-iron. The deflection curve in orange in the newer Shadow Lite Steel S-flex, also cut for a 5-iron. This example is an almost rarity in golf where you have two shafts with the same exact shaft geometry. The only difference is the Shadow Lite has thinner walls throughout the length of the shaft to create a lighter shaft. The signature deflection curve is like it’s DNA. Here is a breakdown of each shaft.

The deflection curve in blue is the original high launch/low bend point Apollo Shadow Steel S-flex shaft that has been cut for a 5-iron. The deflection curve in orange in the newer Shadow Lite Steel S-flex, also cut for a 5-iron. This example is an almost rarity in golf where you have two shafts with the same exact shaft geometry. The only difference is the Shadow Lite has thinner walls throughout the length of the shaft to create a lighter shaft. The signature deflection curve is like it’s DNA. Here is a breakdown of each shaft.

|

|

Shadow |

Shadow Lite |

|

Cut Weight |

111.5 g |

97.8 g |

|

Frequency |

331 cpm |

313 cpm |

|

Torque |

1.74° |

1.94° |

Simply, the thinner the walls or the lighter the shaft with all else the same, the more flexible the shaft will be. As a result of the additional flex, a higher ball flight will occur as you have less material to resist bending forward at impact.

Shaft Balance Point: A Comparison of Apollo Black Steel vs. True Temper Dynamic Gold (Parallel Tip)

While there are no industry standards for stiffness, bend point, kick point or ball flight descriptions from one manufacturer to another, we can still glean good information from what the various manufacturers publish. After all, they do not want to deceive potential customers into choosing the wrong shaft.

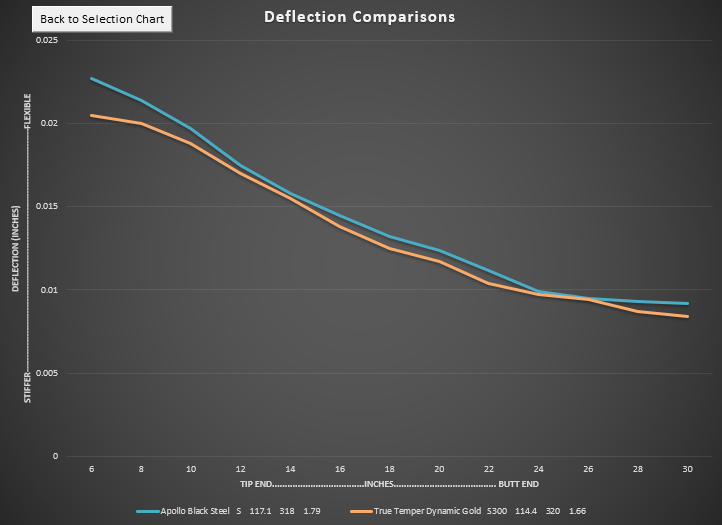

The deflection curve in blue is the Apollo Black Steel S-flex shaft that has been cut for a 5-iron. The manufacturer lists this as a mid-bend point or mid trajectory shaft. The curve in orange is the parallel tip version of the True Temper Dynamic Gold S300 shaft, also cut for a 5-iron. It is listed by the manufacturer as a high bend point or low trajectory shaft. Here is a breakdown of each shaft. The shaft balance point is listed from the tip end of the shaft.

|

|

Black Steel |

Dynamic Gold |

|

Cut Weight |

117.1 g |

114.4 g |

|

Frequency |

318 cpm |

320 cpm |

|

Torque |

1.79° |

1.66° |

|

Balance Point |

51.5% |

50.4% |

These two shafts share very similar weights and frequencies (CPM) and the deflection curves nearly overlap, except for the first 10” of the shaft tip where the Apollo Black Steel is more flexible. Hence the difference in the bend point / ball flight characterization. However, these differences will be very subtle to the end user and likely need a launch monitor to detect the difference in ball flight.

Exploring Tip Stiffness of a Golf Shaft in Depth

Both shafts are identical in length and similar in weight. If you look deeper, the weight distribution of the shaft is a key parameter and not something the manufacturers publish. The shafts’ balance point or distribution of mass located approximately 0.4” higher up the shaft on the Apollo shaft than the True Temper. Why? This has to do with how these two shafts are constructed.

True Temper’s proprietary Variable Wall Technology, the company’s engineers can vary the wall thickness throughout the shaft for enhanced performance. The wall is thinner towards the butt section of the shaft for improved feel and then thickens towards the tip of the shaft for better control and accuracy. In contrast, the shaft blank on Apollo shaft has a universal wall thickness (straight pull). This is one of the differences why one shaft is @ $10 and the other is @ $30 due to the difference in their construction.

True Temper’s proprietary Variable Wall Technology, the company’s engineers can vary the wall thickness throughout the shaft for enhanced performance. The wall is thinner towards the butt section of the shaft for improved feel and then thickens towards the tip of the shaft for better control and accuracy. In contrast, the shaft blank on Apollo shaft has a universal wall thickness (straight pull). This is one of the differences why one shaft is @ $10 and the other is @ $30 due to the difference in their construction.

Shaft Diameter: A Comparison of True Temper Dynamic Gold (Taper Tip) vs. True Temper Dynamic Gold (Parallel Tip)

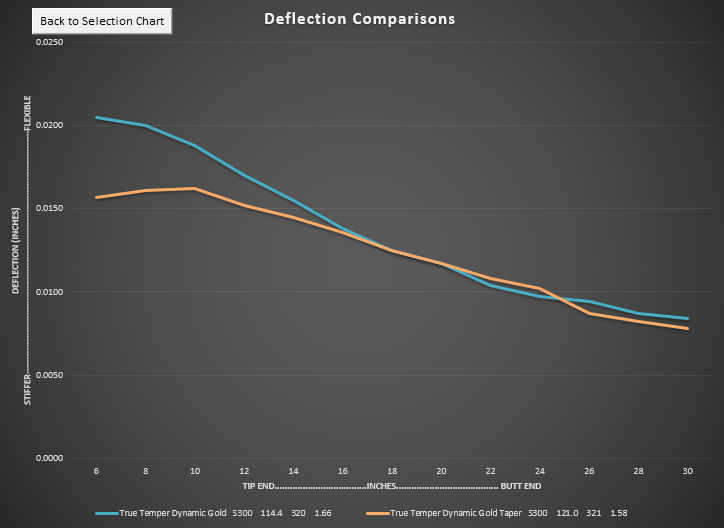

The deflection curve in blue is the parallel tip version of the True Temper Dynamic Gold S300 shaft that we just reviewed. The curve in orange is the 39” taper tip version of the True Temper Dynamic Gold S300 shaft, also cut down for a 5-iron. Both are listed by the manufacturer as a high bend point or low trajectory shaft.

|

Taper Tip |

Parallel Tip |

|

|

Cut Weight |

121.0 g |

114.4 g |

|

Frequency |

321 cpm |

320 cpm |

|

Torque |

1.58° |

1.66° |

|

Balance Point |

50.1% |

50.4% |

If you ever hit the two shafts side-by-side, you will notice a difference in feel and trajectory even though the specifications from the manufacturer are the same. This can be explained if you carefully took measurements of the shaft. The parallel tip shaft has a constant 0.370” tip section for 8.125” from the cut tip to the first step dimension. The taper tip version starts are .355” at the very tip but then tapers to 0.395” at the first step. The larger outside diameter (OD) at the tip section makes the taper tip version more tip stiff than the parallel tip version.

What About Graphite Shafts?

Steel golf shafts are homogenous, meaning they are made of one material. However, graphite shafts are not entirely dependent on geometry, weight, weight distribution and wall thickness for stiffness. The various materials and their fiber orientation on the forming mandrel are also contributing factors.

Summary

Hopefully you can see from the 3 cases studies how diameters and wall thickness can control the shaft deflection and subsequently how and why one steel shaft performs differently from one to another.